Friday, 1 August 2025 Knowledge Articles

Understanding Hydrostatic Crush Pressure in Underground Tanks

When installing underground water tanks, one of the most overlooked site conditions is groundwater. If ignored, it can cause structural damage or even complete tank failure. One critical factor to understand is hydrostatic crush pressure.

What Is Hydrostatic Crush Pressure?

Hydrostatic crush pressure occurs when groundwater surrounds an empty underground tank. With no water inside the tank to counteract the external force, the pressure from the groundwater can compress the tank walls, causing them to collapse inward.

If your site has no groundwater risk, this isn’t a concern. But if groundwater is present — or may be seasonally present — it’s essential to plan accordingly.

Key Consideration for Designers & Specifiers

If groundwater is expected at the installation site, it’s recommended to:

- Use an underground tank certified to AS/NZS 4766:2020

- Include an engineered uplift restraint system

These requirements should be clearly outlined on your consented plans to ensure compliance and correct installation.

How to Prevent Hydrostatic Crush

There are two main ways to mitigate the risk:

1. Use a Certified Underground Tank

The AS/NZS 4766:2020 standard confirms a tank can withstand constant external pressure — even when completely empty and surrounded by groundwater.

Think of it like a submarine: it’s built to handle full submersion without collapsing.

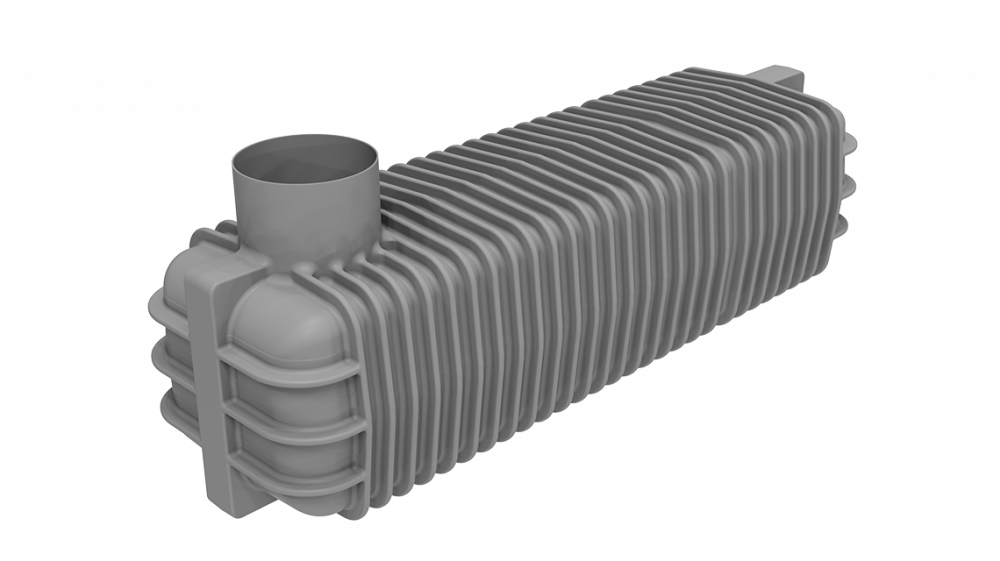

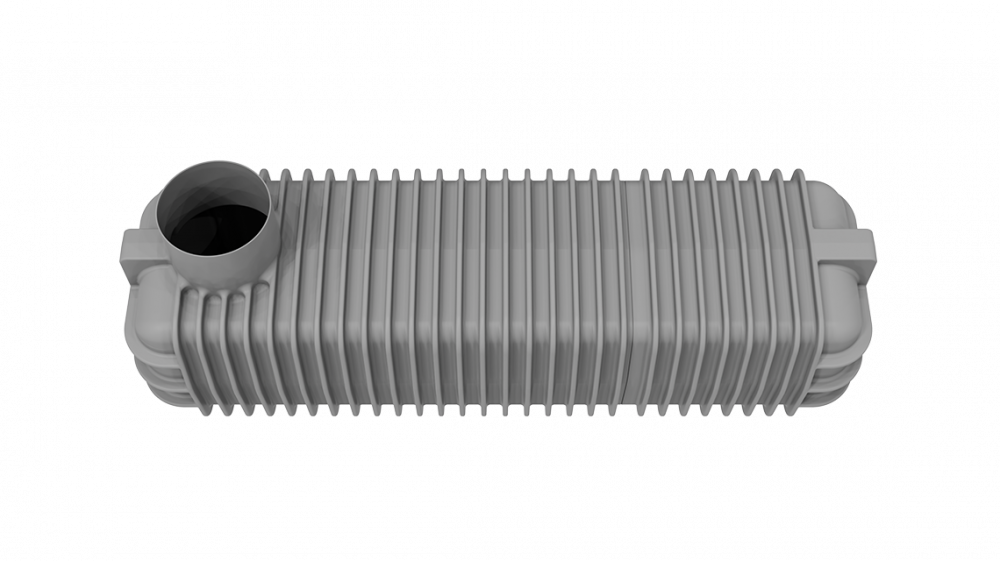

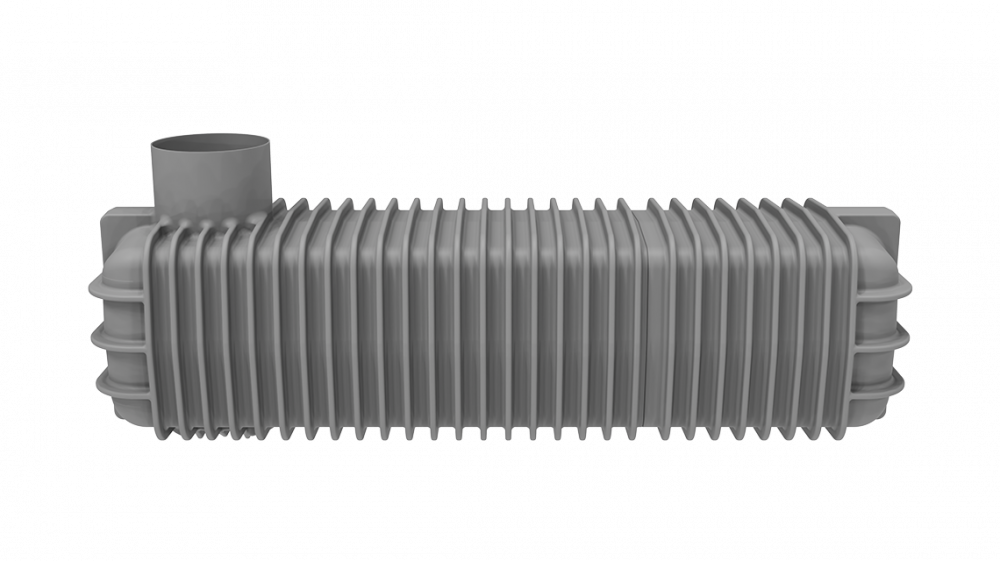

✅ The Promax ENDURO Super Duty Underground Tank is New Zealand’s only tank certified to this standard. It’s engineered to withstand full-time hydrostatic pressure and submersion.

2. Install a Socked Subsoil Drain

A site-specific option is to install a socked subsoil drain at low level around the tank. This system redirects groundwater away from the tank, preventing hydrostatic pressure from building up in the first place.

Hydrostatic Crush vs. Tank Flotation

While both are caused by rising groundwater, they have very different effects:

- Hydrostatic Crush: Groundwater squeezes the tank inward

- Flotation: Groundwater pushes the tank upward, lifting it out of the ground

Flotation is usually managed using restraint systems. But not all restraints are created equal.

Uplift Restraints vs. Installation Anchors

Uplift Restraints

- Fully engineered to prevent flotation during full groundwater rise

- Covered by Promax PS1 certification

- Recommended as standard unless a geotechnical report confirms no uplift risk

Installation Anchors

- Designed to hold the tank in place during installation only

- Not suitable for long-term flotation protection

- Not covered by PS1 and not recommended unless specifically engineered for flotation control

⚠️ Important: You cannot use both systems. If you're using uplift restraints, installation anchors are not required, and vice versa.

Installing Tanks Under Driveways

Tanks placed beneath driveways may benefit from the added weight and structural support above. In practice, these tanks have not shown flotation issues. However, as installation anchors are not PS1-certified, Promax cannot formally guarantee flotation performance under these conditions — even though they often prove sufficient in the field.

Final Thoughts

Groundwater is an invisible but powerful force. If there’s any chance it could impact your site, taking the right precautions can make the difference between a safe installation and a costly failure.

At Promax, we take a safety-first approach. Unless a geotechnical report states otherwise, we assume groundwater may rise to ground level.

Choose a tank engineered for the job — or manage the risk by draining it away.

Need help specifying the right underground tank?

Call us on 0800 77 66 29 or email sales@promax.co.nz to speak with our technical team.