Friday, 1 August 2025 Knowledge Articles

Different Types of Fittings for Industrial Tanks

Looking at Different Types of Fittings for Industrial Tanks. Which One Suits Your Needs?

When selecting the appropriate fittings for Industrial Tanks, understanding the diverse range of options and their specific applications is crucial to ensuring optimal performance and durability.

When you need to connect your tank to pipework and other components, such as valves, sensors, overflows, and fire couplings, choosing the right fittings can make a big difference in the performance and longevity of your tank system.

At Promax, we offer three types of fittings for our industrial tanks, each with their own advantages and disadvantages depending on your specific needs and preferences. Here is a brief overview of the different types of fittings and how to choose the best one for your project.

Stub spigot and backing ring

This is the most secure and robust type of fitting, which is why we call it the "Belt and Braces" of fittings. It consists of a stub spigot, which is a piece of PE pipe welded into the sidewall of the tank, and a metal backing ring, which is attached to the stub spigot with bolts. The backing ring provides a strong and stable connection between the tank and the pipework and allows for some flexibility and movement in case of ground shifts or pressure changes. This type of fitting is ideal for large-diameter pipes and high-pressure applications, where you need a reliable and leak-proof connection. However, this type of fitting is also the most expensive and requires an expansion joint that absorbs shocks and vibrations and protects the tank warranty.

PE pipe

This is a more cost-effective and simple type of fitting, which consists of a piece of raw PE pipe welded into the sidewall of the tank. It is connected to the pipework with a compression shear band coupler (PlumbQwik or Gibault), which is a plastic device that clamps around the pipe and seals it. This type of fitting is suitable for overflow s and small inlet pipes, where the pressure and flow are not too high. It is also easy to access and replace if needed. However, this type of fitting is not as secure or resilient as the stub spigot and backing ring, and it may leak or fail if the pipe is too large, or the ground moves too much. We recommend using this type of fitting only for pipes up to 225 mm in diameter.

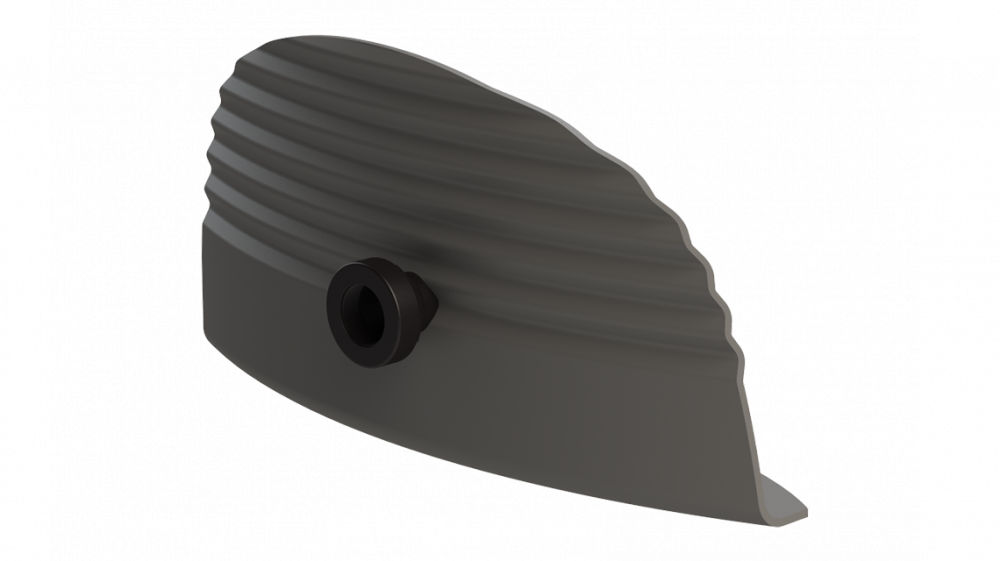

BSP spigot adaptor

This is the cheapest and simplest type of fitting, which consists of a threaded spigot adaptor welded into the sidewall of the tank. It can be either male or female, depending on the type of thread you need. This type of fitting is suitable for small fittings, such as sensors, valves, or intakes, where you need a threaded connection. It is also easy to install and remove if needed. However, this type of fitting has a limited range of sizes, from 32 mm to 110 mm, and it may not be compatible with some types of pipework or components. It is also not very strong or flexible, and it may crack or leak under stress.

How to choose the best type of fitting for your project

- The type of fitting you need depends on several factors, such as:

- The size and type of the pipework and components you are connecting to the tank

- The pressure and flow of the water or liquid in the tank and the pipework

- The location and environment of the tank and the pipework, such as the soil conditions, temperature, and seismic activity

- The budget and specifications of your project

To help you choose the best type of fitting for your project, we recommend that you consult with an expert, such as our team at Promax, who have extensive knowledge and experience in industrial tank fittings. We can also work with engineers, consultants, and contractors to ensure that your tank system meets the highest standards of quality and compliance. We can provide you with drawings, plans, and quotes for the tank and the fittings, and advise you on the best options and practices for your project.

At Promax, we are proud to offer the best range of industrial tanks and fittings in the market, with a variety of sizes, shapes, and colours to suit your needs and preferences. Our tanks are made from high-quality polyethylene, which is strong, durable, corrosion-resistant, and UV-stabilized. Our tanks are also certified to AS/NZS 4766 standards, which means they meet the highest requirements for design, manufacture, and testing.